The masonry system I’ve been describing is appropriate for building structures on the moon, other planets, and in space. This is what we’ll be looking at today.

The cost of sending any material into orbit is very high. Currently this cost is estimated at around $5,000 per pound, according to PhysOrg. If we can send less material into orbit, and instead use the materials found in space, we can greatly reduce the cost of our missions in space.

The moon has long been considered a potential base for deep space exploration. This is because the cost of leaving lunar orbit is a small fraction of the cost of leaving earth orbit; it takes a lot less energy to launch from the moon (less than 5%). Currently NASA plans to have a habitable moon base by 2024; although this plan is currently being brought under scrutiny by the Obama administration.

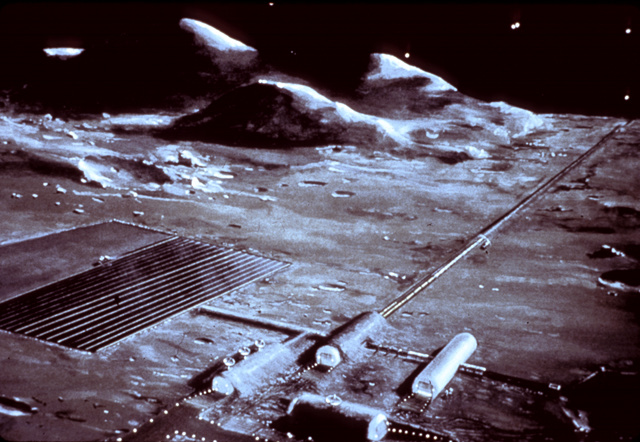

The surface of the moon is comprised of a mix of rocks, minerals and clays not entirely unlike earth. It would be possible to make masonry units from the rock and mineral mixes found on the moon. This material could be surface mined, mixed, and formed into blocks by robotic equipment. Here is an artist’s conception of lunar mining.

The block system described on this blog would lend itself readily to robotic production, due to the simple two-piece mold and ease of production. Once formed, these blocks could be fired (heat treated) by a solar kiln, where mirrors reflect and focus solar energy to provide sintering and solidification to masonry units. Alternatively, a small addition of cement-like material could help consolidate and form these blocks.

Robots could then be used to assemble a structure on the surface of the moon. The interlocking feature, together with a woven tensile element, provides a relatively simple assembly method with a robust design and high strength. A spherical section (e.g., dome) would be an ideal configuration for a lunar structure.

Once assembled, the dome would be lined with a bladder and inflated to provide a habitable structure prior to human arrival. The mineral composition of the lunar surface provides an appropriate material to block out cosmic radiation and harmful high energy particles. The high specific heat and thermal mass of this structure would greatly dampen the extreme temperature swings which occur between lunar day and night. The effects of extreme hot and extreme cold would be greatly reduced.

The unprecedented success of the robotic systems on the recent Mars Rover missions indicates that robotic units are capable of performing adequately when asked to perform rather sophisticated maneuvers and manipulations. Honeybee Robotics was involved in developing and deploying these robotic systems on the Mars missions. I have begun preliminary conversations with their engineers on my approach, they seem interested.

Aside from the moon and a similar sort of deployment on Mars, this masonry system could also be used to build self-contained satellites as complete spheres. These could be made for near earth orbit, for “way stations” throughout our solar system, to store material such as fuel, water and oxygen. They could also be placed on larger asteroids in the asteroid belt, such as 253 Mathilde.

This masonry system provides a compelling set of reasons for its deployment in extraterrestrial applications. First, we greatly reduce the cost of sending material into orbit from earth. Secondly, it can be made using the materials found on the moon, Mars, etc. Third, it can be produced and assembled robotically. Finally, this system blocks out harmful cosmic radiation, takes advantage of the high thermal mass to dampen out extreme temperature fluctuations, and provides an appropriate architectural shell for housing a bladder, to provide a suitable atmosphere for human habitation.

Next time we’ll take a look at retaining walls and landscaping applications for this block system. This is a very large and growing market for masonry units.

Hello, an amazing Information dude. Thanks for sharing this nice information with us. Semi Face Brick in South Africa

ReplyDelete