Previously I described how the shape of the dimp masonry units describes a mathematical or geometric limit to design. If triangular block are made on a simple two-piece mold, and blocks are to have the greatest possible interlock, then the shape I have uncovered is the limit within these parameters. However, this shape as defined by these limits is not necessarily the best performing masonry unit. Slight adjustments to these shapes make them more robust, easier to use and ultimately stronger.

When describing these shapes, I refer to a “key” and a “keyway”; the key is a half-diamond shaped protuberance that sticks out from the block, the keyway is a half-diamond shaped recess that goes into the block. At the limit of the dimp design, the key comes to a sharp triangular point. This point will focus stress. The bottom of the keyway recess also comes to a sharp triangular valley, which will also focus stress at this specific location.

Instead of having these sharp points at the key & keyway, they are “rounded off” so that forces are not focused at those locations. Whatever amount of material is removed from the tip of the key must be added to the valley of the keyway, so that the key & keyway still line up and properly interlock between adjacent blocks.

How much the key gets “rounded off” is a tricky question. It may be rounded by a simple radius, or it may be made to have a parabolic profile. If the key is rounded with a simple radius, then a size of radius must be selected. If too small of a radius is selected, then force will still be focused at a relatively small area. If too large of a radius is selected, then the interlocking aspect of the key and keyway will be substantially reduced. What is the optimum amount to round the tip of a key & keyway? Should it be round or parabolic in shape?

These questions are truly interesting because this brings us to the intersection of art and science. The equations required to describe this situation would be so utterly complex as to be practically unmanageable. A number of competing mathematical approaches to solving this problem would provide different answers and different ways of viewing the problem.

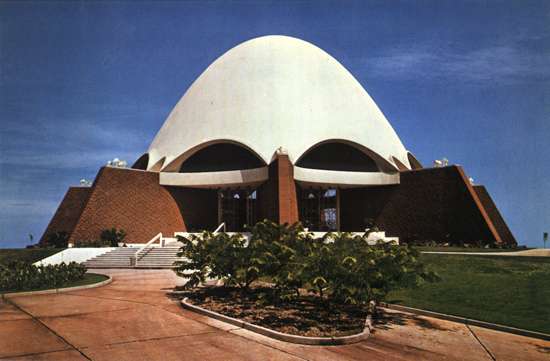

Instead, a person looks at the key and keyway and uses an intuitive sense to imagine: “removing this much would make it weak; removing that much would just not be enough; it seems like this particular arrangement feels about right.” This sort of exercise draws on the experience, knowledge, skill and artistry of a masonry designer to provide an informed design decision. Hard science and mathematics are left behind and art is picked up. It is as though you feel it in your bones, like Brunelleschi and his dome. This all occurs at the nexus of art and science.

A baseball pitcher may not have a full knowledge of acceleration, gravity, drag, rotational inertia, etc., but is able to use these principles to dramatic and skilled effect. So it is when a person looks at a structure and imagines the weight, or force, or response of an arrangement to gravity or other stresses. There is an intuitive knowledge which is developed with experience, study and practice. These experiences inform the masonry designer and create a bridge from science to art.