Here in western New York State, this winter (2024-2025) has been pretty brutal. We had the coldest January in decades, and February is providing more of the same. This extremely cold weather is due to oscillations of the polar vortex, which dip down into lower latitudes and allow cold arctic air to occupy temperate zones to the South. These arctic oscillations are ironically due to global warming, as temperatures in the arctic have been record-breaking warmth. As I type this, it is currently 28 degrees F in Anchorage, Alaska; it is 8 degrees F here in western New York State.

One of the effects of this prolonged cold has been increased snowfall, due largely to lake effect snow, as the cold air passes over the Great Lakes it creates snow bands on the leeward, eastern edge of the Great Lakes. This increased snowfall has created a hazard to many buildings in its path: collapsing roofs.

A spate of collapsing roofs has occured over the past few days and weeks, as the weight of accumulating snow compromises roofs which are not designed to handle such heavy loads. These events include everything from modestly sized residential homes, to commercial buildings, to large manufacturing facilities. All of these types of structures have experienced roof collapse due to the large snow loads they've been subject to.

As climate change continues, these weather patterns are expected to continue as well. The polar vortex oscillations will continue into the future, and we can expect correspondingly brutal cold and increased snow, with a continuing possibility of collapsing roofs due to large snow loads. In my own experience, over the past ten years or so, the polar vortex oscillations are noticeably increasing. We experience prolonged periods of extreme cold here in western New York State as climate change progresses.

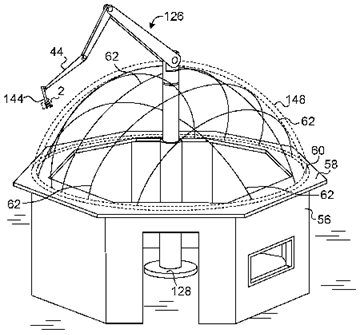

Personally, I do not worry about the possibility of a collapsing roof. This is due to the high compressive strength of concrete block masonry arched and domed roofs which are on top of all my masonry buildings. This structural arrangement is made stronger by additional weight. These roofs are squeezed together under the added weight of a snow load, which is how they are strongest. These structures do not suffer from the failures of wooden and metal trussed roofs. They are simply stronger under the conditions of high snowloads.

The benefits which concrete block masonry arched and domed roofs provide, which I've been describing for years on this blog, include: high strength, high thermal efficiency due to thermal mass benefits, fire safety, termite safe, low cost, ease of assembly, beautiful designs, and long life spans. It occurs to me that safety from a collapsing roof due to high snow loads should be added to this list of benefits for concrete block masonry arched and domed roofs.