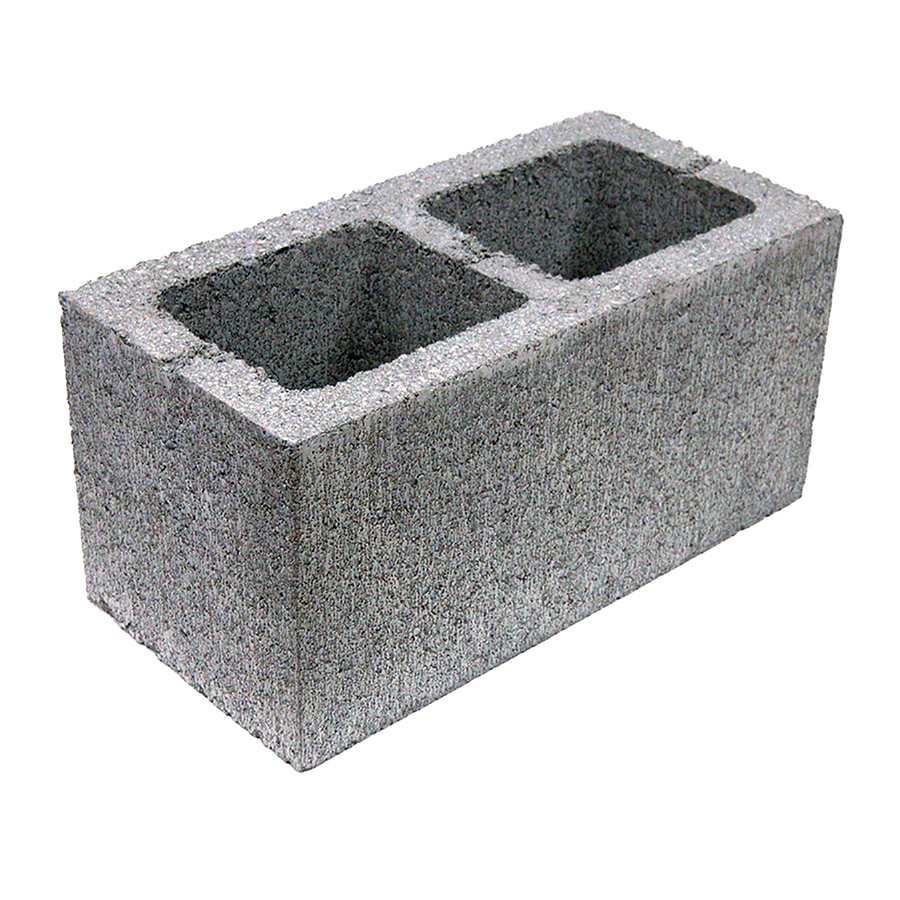

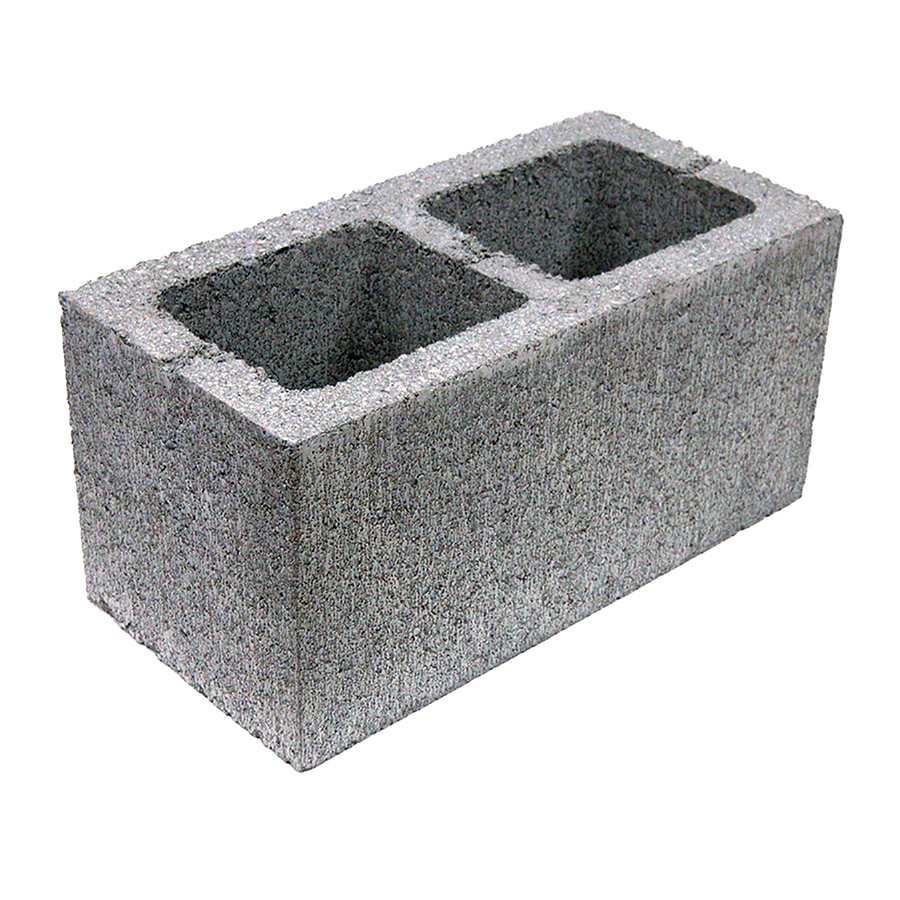

Manufactured concrete block represents a great success story

of the 20th century. An

entire global industry has developed and evolved into a high state of

efficiency and economy, all based on manufactured concrete block. This technology thrives in virtually every

country on earth: the traditional, rectangular concrete masonry unit (CMU) is

produced inexpensively and with an engineering knowledge which is well

understood and successfully put into practice by block producers globally. The result is something we all tend to take

for granted: high-strength, consistently dimensioned, inexpensive, rapidly

produced CMU’s which are suitable for vertical walls in virtually any type of

building, including residential, commercial, public buildings and

infrastructure. With such a successful

model of production, distribution, assembly and availability already well

established and in place, what –if any- new developments can research and

development (R&D) add to this existing industry and practice?

My own work as a masonry designer has addressed this question

for 25 years now. I will attempt to

summarize the areas of potential future growth, development and design which

this robust industry has left essentially unfulfilled. A look at current areas of research conducted

by various segments of the scientific and engineering world indicate areas

which stand to benefit and develop rapidly from the existing engineering

practices of the concrete block industry.

The research and development proposed here hold the potential to

transform the concrete block industry’s offerings into an entirely new realm of

products which will provide better building systems at a lower cost on a global

basis. A modest effort in research and

development will reap huge benefits for humanity; it will grow the concrete

block industry and make superior, affordable, beautiful and holistic construction

available for all.

One specific area of current research which has garnered

significant attention from scientists, engineers, designers and practitioners

is the idea of topological interlocking structures. “Topological”

refers to “Topology (from the Greek τόπος, "place", and λόγος,

"study") [which] is the mathematical study of shapes and topological

spaces. It is an area of mathematics concerned with the properties of space

that are preserved under continuous deformations including stretching and

bending, but not tearing or gluing. This includes such properties as connectedness continuity and boundary. Topology developed as a field of study out of geometry and set

theory, through analysis of such concepts as space, dimension, and

transformation. Such ideas go back to Leibniz,

who in the 17th century envisioned the geometria

situs (Greek-Latin for

"geometry of place") and analysis

situs (Greek-Latin for

"picking apart of place"). The term topology was introduced by Johann Benedict Listing in the 19th century, although it was

not until the first decades of the 20th century that the idea of a topological Space was developed. By the middle of the

20th century, topology had become a major branch of mathematics” (taken from

Wikipedia).

Currently, concrete block

design and practice do not provide for topological construction. The standard rectangular concrete block

designs (with which we are so familiar) can only be used to create straight

vertical walls and square corners. A few

designs allow for a slightly curving wall, which have found use mainly in

retaining walls and landscaping applications.

Other novel designs allow for slight variations to the basic idea of a

vertical wall, including corners which occur at 45 degrees and so on. Current concrete block designs are far from

providing a full expression of topology.

Curving walls –such as those provided by landscaping applications- only

curve in one dimension, like a cylindrical surface, and do not allow curvature

in two dimensions, like a spherical surface.

A form of concrete block known as “articulated block” (shown above and below) does some

interesting work as an erosion-arresting embankment material. Articulated block do not interlock in the

plane being assembled; blocks can slide in and out of the assembly. There are some great articulated block

designs being developed though.

Currently, concrete block

design and practice do not provide for topological construction. The standard rectangular concrete block

designs (with which we are so familiar) can only be used to create straight

vertical walls and square corners. A few

designs allow for a slightly curving wall, which have found use mainly in

retaining walls and landscaping applications.

Other novel designs allow for slight variations to the basic idea of a

vertical wall, including corners which occur at 45 degrees and so on. Current concrete block designs are far from

providing a full expression of topology.

Curving walls –such as those provided by landscaping applications- only

curve in one dimension, like a cylindrical surface, and do not allow curvature

in two dimensions, like a spherical surface.

A form of concrete block known as “articulated block” (shown above and below) does some

interesting work as an erosion-arresting embankment material. Articulated block do not interlock in the

plane being assembled; blocks can slide in and out of the assembly. There are some great articulated block

designs being developed though.

The design of CMU’s which

allow for full topological expression provides the ability to use block to make

roofs and complete curved structures

(e.g. complete spheres, ovals, elliptical, catenary and other designs). The design ability which can create a full

expression of topology allows the use of high strength, affordable, rapidly

produced building components which provide all the benefits of concrete block,

including: fire resistance, termite resistance, rot resistance, building

longevity, resale value, solidity, appearance, and the ability to withstand

extreme weather events (hurricanes, tornadoes, typhoons, storm surges,

tsunamis, etc.). The creation of CMU

designs which allow for full topological expression will create an entirely new

architectural vocabulary for building with concrete block, and will create

entirely new markets for concrete block.

If an interlocking aspect is included in the

masonry unit then the topology in masonry is made particularly more effective. One striking example (which has fueled much of

the current research) is the failure of thermal tiles on the space shuttle

Columbia. Because they did not interlock, these topological tiles

(designed to wrap around the shuttle: topologically) were free to move and

dislodge themselves from their protective positions since they were held in

place only by adhesive, leaving the shuttle vulnerable to catastrophic reentry

into the earth’s atmosphere. Researchers

were quick to realize that if an interlocking aspect of each masonry unit (or

tile) were incorporated, then the geometry of the individual masonry units

would have helped keep them in their proper location (anchored by adjacent

masonry units) and prevented them from being removed. Furthermore, researchers have realized that

topological interlocking masonry units (or tiles) would not suffer complete,

systemic failure if one of these masonry units were damaged: the other adjacent

and surrounding tiles would stay in place, even if one tile broke or was

removed. By including the interlocking

feature into the masonry unit itself, a separate independent connector is not

required.

While this idea of the

beneficial nature of interlocking masonry units is illustrated by the Columbia

tragedy, it holds great significance for the less exotic application of

buildings here on terra firma. To fully

understand this, we will look at the current state-of-the-art for masonry engineering

analysis. Examining a masonry arch, the

current engineering model makes 3 assumptions: 1. Masonry units have infinite

compressive strength; 2. Masonry units have no tensile strength; 3. Masonry

units never slide against each other (they remain in their fixed position). We will concern ourselves here with the third

assumption, the idea that masonry units in an arch (known as voussoirs) never

move relative to one another.

In reality and in

practice, voussoirs are known to move against each other in a masonry

arch. When this occurs, the arch can be

significantly weakened and this movement of voussoirs can result in failure and

collapse of the arch. A catenary thrust

line is an imaginary line of force which exists in the wall thickness of the

arch. Catenary (from Latin “catena” or

chain) is the shape of a hanging chain or cable under gravity; if this shape of

a hanging chain is inverted, then a catenary thrust line is generated. As long as this imaginary thrust line does

not touch or exit the arch wall thickness, the arch will remain standing and

stable. If the imaginary catenary thrust

line touches or exits either the inner surface (intrados) or the outer surface

(extrados) of the arch, then a hinge will form at that location. Several hinges allow a mechanism for movement

of the arch, resulting in a buckling or folding of the arch about these hinge

locations, leading to failure and collapse of the arch. However, if voussoirs possess an interlocking

feature such that they are not free to move relative to any adjacent

(interconnected) voussoirs, then the catenary thrust line will not touch or

exit either the intrados or extrados of the arch due to movement. Thus interlocking masonry units in an arch

are fundamentally much stronger, more robust and more stable than masonry units

which do not interlock.

The creation of an effective

interlocking feature on a topological masonry unit produced on a standard

conventional block machine is a very real challenge for the masonry

designer. Interlocking features are

actually commonplace in standard (non-topological) blocks: the ‘top’ and ‘bottom’

of the concrete masonry unit can readily incorporate interlocking

features. A wide variety of designs is

possible if the interlocking feature does not include topological arrangements,

but the designer is still limited to building straight vertical walls. In order to provide an interlocking feature

for a topological masonry unit, the sides of the block must be used (not just the

‘top’ and ‘bottom’ of the block) as sites of interlock. The difficulty here is that a block mold must

be readily stripped from the block without any undercut, or draft, or negative

angle. In other words, an interlocking

feature on a topological block will create undercuts: an interlocking

topological block simply will not release from a mold. This contradiction can be overcome by

symmetry and design.

Another difficulty in

creating an interlocking topological block on a block machine is the ability of

the mold cavity to be filled completely, evenly and homogeneously. If a section of the mold near the ‘bottom’ of

the block has an overhanging feature (steel mold above it) then it will not

fill as readily as an open cavity which allows the concrete mix to flow into it,

unimpeded. A section of mold cavity

which has an overhanging feature will impede the flow of concrete into the

cavity, resulting in segregation of aggregate.

This segregation of aggregate will typically result in a weakened

section of the block where larger aggregate is prevented from filling as easily

as in an open mold cavity. Lack of

larger aggregate in a filled mold section creates a weaker section of concrete

as a result.

In addition to sections

of mold being less than ideally filled due to overhanging mold parts, there is

another problem where a section of mold cavity at the ‘top’ of the mold has an

open space below it (at the ‘bottom’).

This will create an overhanging projection of block, which is

unsupported from underneath (at the ‘bottom’).

These cantilevered features of block are prone to cracking and breaking,

especially upon handling as the un-cured block leaves the block-making machine.

How can a topological

interlocking masonry unit be created in a manner that provides adequately

filled mold cavities at the ‘bottom’ of the mold, while also not creating weak

cantilevered sections at the ‘top’ of the mold?

This is a very interesting design challenge; one which I hope will

attract the efforts and solutions of other designers.

Catenary thrust line analysis of

masonry domes is another area of current research. Computer models which digitally process the

applied stress and the resulting strain as hinge mechanisms are used to develop

visual models. Catenary thrust line

analysis is also used to digitally analyze a computer 3D model as a tool for

designing buildings.

Biomimicry/Biological Design as a

source of masonry design is ripe with potential. “Nature’s masons” include single-celled radiolarian

and foraminifera, coral, sea anemones, sea horses, turtles and tortoises, Thor’shero shrew, and an endless array of life’s other innovative design solutions.

Anisotropy in manufactured concrete

block has not been fully utilized with current block designs. Vertical block walls are made with the weaker

axis of the block facing horizontally, to the outside. It is possible to orient the block so that

the high strength axis faces outside, resulting in a significantly stronger

building.

Robotic assembly is still in its early

stages regarding masonry, but real progress continues in this field. Robots may play an important role in the

future of masonry. Robotic assembly may

have an early adaptation for situations that might endanger a human mason, such

as radiation or other hazardous materials.

Construction Robotics is one company that is currently successfully developing

robotic masonry.

3D Printing is also in its early

stages, but is expected to develop with time.

3D printing should find early use in masonry applications which require

a unique masonry piece, such as at the intersection of two arches, or to allow

conduit or openings, etc. In this role it will be cost effective fairly

soon.

.jpg)