Thrust force lines must be kept within wall thickness for a structure to remain standing; this makes wall thickness critically important. The triangular interlocking masonry system described on this blog can provide different wall thicknesses through different techniques.

A wall in a hemispherical dome is considered "thin shelled" if the wall thickness is 10% (or less) of the radius. This 10% proportion is considered safe for a full hemisphere which goes 90 degrees from crest to base. If a spherical dome is a segmental section which only goes 70 degrees from crest to base, then a wall thickness of 4% proportion (thickness to radius) is considered safe. This shows how dramatically stress increases at the bottom of a spherical dome.

A spherical dome under gravity is subject to "hoop" stress (like lines of latitude, horizontal) which varies from the crown down to the bottom edge. This stress is completely under compression from the top center down to the haunch (51.820 from vertical). Below the haunch there are tensile forces pushing out, which grow stronger and tend to introduce cracks at the bottom of the masonry dome. These tensile hoop forces at the bottom of a masonry dome are typically resolved by either a tension ring, or a massive abutment, or both.

Historically masonry analysis refers to “lunes” which are like the sliced sections of an orange peel. Each lune is viewed as a discreet arch section for the purpose of stress analysis. From the top of the lune down to the base of the dome, the stress increases as the weight increases. The wall thickness increases accordingly to accommodate this increased stress.

Although vertical cracks are known to develop at the bottom of large domes, this does not necessarily make these domes unsafe. Many large domes with cracks at their bases are known to have stood for centuries, and are standing still; such as the Hagia Sophia, the Pantheon, and many others.

A wall in a hemispherical dome is considered "thin shelled" if the wall thickness is 10% (or less) of the radius. This 10% proportion is considered safe for a full hemisphere which goes 90 degrees from crest to base. If a spherical dome is a segmental section which only goes 70 degrees from crest to base, then a wall thickness of 4% proportion (thickness to radius) is considered safe. This shows how dramatically stress increases at the bottom of a spherical dome.

Wall thickness may be increased by simply making the bricks thicker. That is, the dimension of the block from outside surface of the dome to the inside of the dome can be made larger for a thicker wall. The center of the wall, at midway between outside and inside, is always an axis of symmetry for the interlocking features of the block. This means that different thicknesses of block can be used together; they will still interlock and connect to each other. Thinner blocks can be placed on top of thicker blocks.

Wall thickness can also be adjusted by using a core or depression or cavity within the block. This technique does not change wall thickness from inside to outside the dome, but within the block itself. A larger core (or hole) will produce thinner, lighter block. (It is useful to note that standard rectangular concrete block is also typically hollow, and have cores). Different core sizes can be used on a given mold. This technique has been used historically by ancient master masons, including the Pantheon with its “coffers” on the dome interior. (The first block which I had mass-produced on a block machine all had a hollow triangular core, they work well).

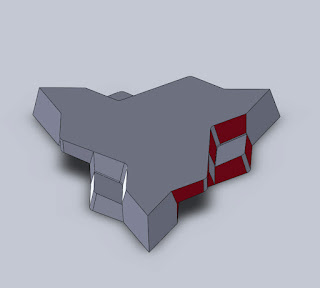

Thickness can also be adjusted by having multiple wythes, or layers of block, like layers of onion skin. This arrangement is recommended for applications which require a high safety factor, including tornado shelters, hardened structures, blast resistant structures, etc. This technique of multiple wythes can also be used at the base of very large domes to resolve thrusting forces. The strength of a structure built with concentric wythes or layers of triangular block can be further increased by weaving the blocks together with a tensile element, like steel cable.

No comments:

Post a Comment