The block system described in this blog readily lends itself to being made with glass. Today we’ll take a look at glass block, and how it would be suitable for this masonry system.

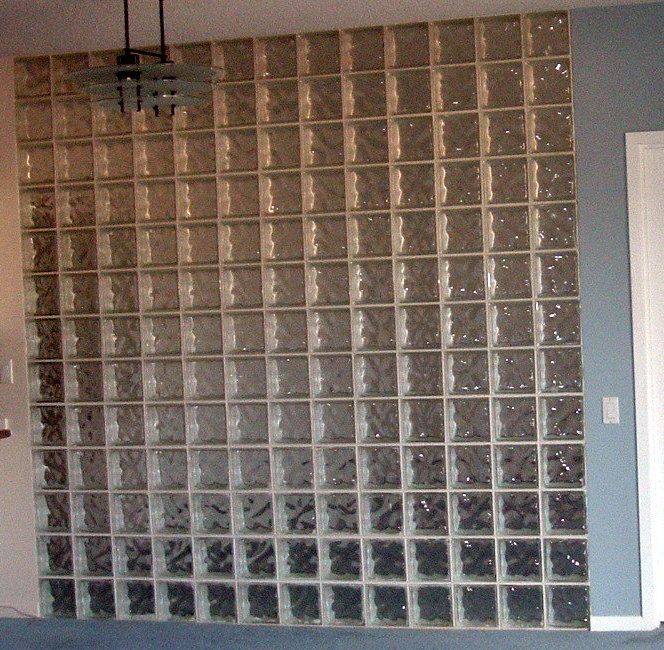

Glass block has become a fairly widespread construction material. As with concrete block, glass block are currently limited to square and rectangular blocks. This limits the architectural applications of glass block to straight vertical walls and square corners. Some block designs include curved corners, but currently no glass block can be used for spherical or dome sections, as I’m proposing here. It’s interesting to me how regular glass block today says “1980’s” and is not considered current, or ‘in vogue.’

Glass block is manufactured by first forming two pieces of glass, and then joining them while the glass is still warm enough to be moveable (at around 800 degrees F). The two pieces are pinched together in a two-piece mold and allowed to anneal, or cool slowly to reduce thermal stresses and obtain a thermally stable object. If the hot glass is not properly annealed, it will crack some time after it is removed from heat.

Hollow glass block creates a decent thermal insulator, and saves heating and cooling requirements for a given building.

Interestingly (perhaps counter-intuitively) glass has a high strength: higher than concrete in some cases. The theoretical strength of glass is very high, and is only reduced by small surface flaws which create starting points for cracks to begin and significantly lowers the actual strength of glass.

Glass can be greatly strengthened by using a technique called ‘ion substitution.’ Glass typically is made with a flux agent, which lowers the melting temperature of the glass. Sodium is a common flux, and is typically found in silicate glasses. If a sodium silicate glass is immersed in a heated bath, comprised of (for example) potassium compounds (e.g. KOH), then the potassium will migrate into the glass, and replace sodium. Potassium is larger (ionic radius) than sodium, so it ‘stuffs’ the glass and creates compression in the glass; resulting in a much stronger glass. This method could be used to create very high strength architectural glass block.

The block system I’ve been describing in this blog is made on a two-piece mold, without any undercut. This is what is required to make hollow glass block. The block system I’ve been describing is appropriate and suitable for producing hollow architectural block.

The glass block produced from this masonry system can be used to assemble spheres, domes, arches, straight walls, and various combinations of these architectural elements. These blocks will all interlock, they are disposed to conjugate shearing without breaking, they can use a series of tensile elements (e.g., steel cable, Kevlar, etc.) to provide a much higher strength to the entire structure.

Glass block can also be used together with concrete block. This is important because glass block is more expensive than concrete, so it can be used as a highlight feature, and bring some dramatic lighting elements to an overall structure. Glass block can also be used to build a small dome, which could be incorporated as a cupola, or an architectural feature within a building. Imagine a glass dome at the top of a foyer or entryway into a building or house.

The symmetry and hexagonal elements inherent to this masonry system produces a ‘snowflake’ effect, where the architecture has a close resemblance to the beauty and symmetry found in snowflakes.

Have you already created prototype of this glass brick?

ReplyDeleteYes, I have.

ReplyDeleteresidential electrical services

ReplyDelete