I am getting ready to tile my bathroom, so I thought this would be a good occasion to talk about tiling.

The basic steps in tiling today involve gluing the tile to a substrate (concrete floor, etc.), and then grouting the space between the tiles. The tiles are glued with either thin-set mortar or mastic. After tiles are set, mortar is applied between the tiles. This mortar is then usually sealed, and allowed to cure.

There is a long history of exquisite tiling from ancient sites and across much of the globe, it endures and remains functional and vibrant. Here is beautiful tile work from Delphi, Greece.

Here is an ancient Arabesque tile showing fractal geometry.

Here is an ancient Assyrian tile, with a floral motif.

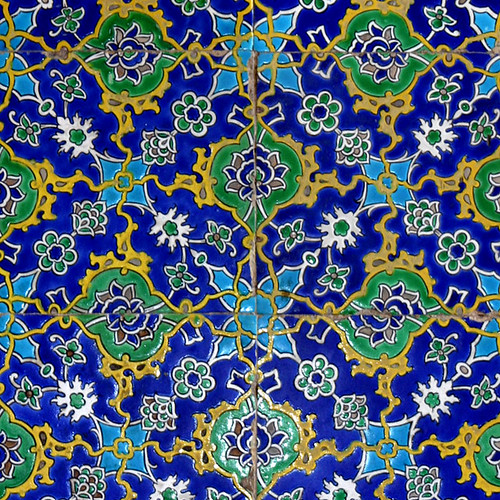

Here is tile from the Topkapi palace, in Istanbul, Turkey.

The Topkapi tiling as an interior arrangement, masterfully executed.

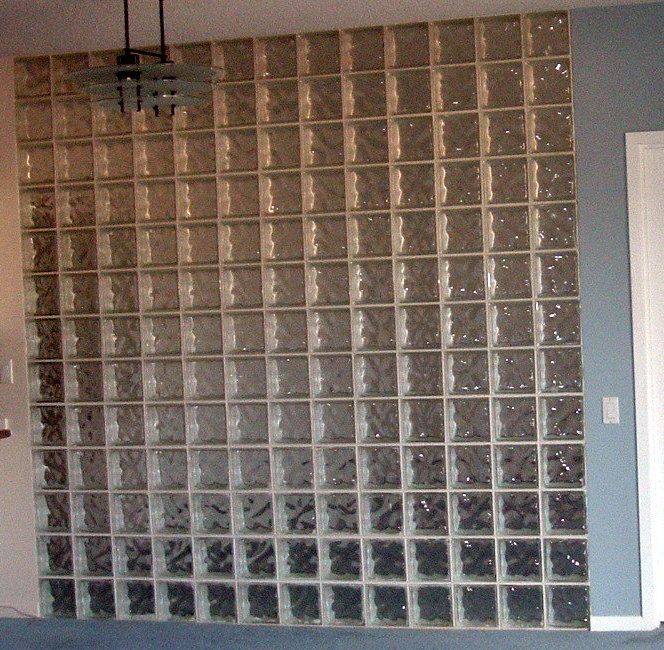

Today most tiles are made as mass-produced unit shapes, which fit together according to a regular repeating pattern, like squares, or triangles or hexagons, etc.

In the world of mathematics, tiling is defined as a two-dimensional pattern resembling a tiled surface. This gets pretty interesting. Regular triangles can tile, squares can tile, hexagons can tile, octagons can tile; but pentagons can NOT tile. If you try to tile together pentagons on a flat surface, you get a gap. Geometers call this gap a “frustration.” Five-fold symmetry does not appear to lend itself to tiling.

Roger Penrose realized that five-fold symmetry could in fact be used for tiling, if done in a quasi-periodic arrangement involving two shapes. There is no regular repetition of geometry, but instead a random element of arrangement which completes the mathematical task of tiling a flat surface. This creates some beautiful patterns. This makes for fun tiling!

The basic steps in tiling today involve gluing the tile to a substrate (concrete floor, etc.), and then grouting the space between the tiles. The tiles are glued with either thin-set mortar or mastic. After tiles are set, mortar is applied between the tiles. This mortar is then usually sealed, and allowed to cure.

There is a long history of exquisite tiling from ancient sites and across much of the globe, it endures and remains functional and vibrant. Here is beautiful tile work from Delphi, Greece.

Here is an ancient Arabesque tile showing fractal geometry.

Here is an ancient Assyrian tile, with a floral motif.

Here is tile from the Topkapi palace, in Istanbul, Turkey.

The Topkapi tiling as an interior arrangement, masterfully executed.

Today most tiles are made as mass-produced unit shapes, which fit together according to a regular repeating pattern, like squares, or triangles or hexagons, etc.

In the world of mathematics, tiling is defined as a two-dimensional pattern resembling a tiled surface. This gets pretty interesting. Regular triangles can tile, squares can tile, hexagons can tile, octagons can tile; but pentagons can NOT tile. If you try to tile together pentagons on a flat surface, you get a gap. Geometers call this gap a “frustration.” Five-fold symmetry does not appear to lend itself to tiling.

Roger Penrose realized that five-fold symmetry could in fact be used for tiling, if done in a quasi-periodic arrangement involving two shapes. There is no regular repetition of geometry, but instead a random element of arrangement which completes the mathematical task of tiling a flat surface. This creates some beautiful patterns. This makes for fun tiling!